Yuniti e Sebetsang ea ho Recycling ea Flux bakeng sa ho Reka

Tlhaloso ea Sehlahisoa

Ho khutlisa mocheso le tšebeliso ea litšila ho bolela mokhoa oa ho khutlisa le ho sebelisa matla a mocheso a teng ka har'a gase (joalo ka gase ea mocheso o phahameng oa mocheso), mokelikeli (joalo ka metsi a pholileng) le lintho tse tiileng (joalo ka litšepe tse fapaneng tsa mocheso o phahameng). mocheso o teng o tsoang nakong ea tlhahiso ea indasteri.

Thempereichara ea gase ea flue ea sebopi sa hot dip galvanizing e ka ba 400 ℃, 'me mocheso o mongata oa litšila oa khase ea flue o ka sebelisoa hape.Baetsi ba bangata ba ntša mocheso ona ka ho toba, ba baka tšenyo ea matla.Ha e kopantsoe le theknoloji ea pompo ea mocheso, karolo ena ea mocheso e ka sebelisoa hape ho theha boleng ba moruo bakeng sa feme.

Lintlha tsa Sehlahisoa

- Ka kakaretso, e ka sebelisoa ho etsa metsi a chesang, ho futhumatsa, ho pholisa le ho omisa.Sehlopha sa k'homphieutha se ka hlophisoa feela ka mor'a ho utloisisa mocheso oa litšila le ho tsosolosa mocheso oa mokhoa o mocha.Ha mocheso oa litšila o ka finyella tlhokahalo ea matla a mocheso oa mokhoa o mocha, sesebelisoa sa ho tsosolosa mocheso oa litšila se ka sebelisoa ka ho toba bakeng sa phapanyetsano ea mocheso.Ha mocheso oa litšila o sitoa ho finyella tlhokahalo ea matla a mocheso oa mokhoa o mocha, mocheso oa litšila o ka sebelisoa bakeng sa ho futhumatsa pele, 'me mocheso o sa lekaneng o ka tlatsetsoa ka thepa ea pompo ea mocheso, kapa thepa ea ho futhumatsa e teng.

Boemong bofe kapa bofe, phello ea ho boloka matla e totobetse haholo ho feta ea mocheso oa pele oa litšila, e le ho finyella morero oa ho fokotsa tšebeliso ea matla le ho ntlafatsa katleho.

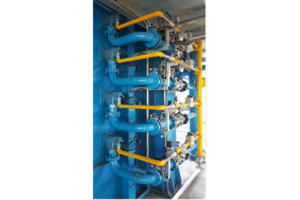

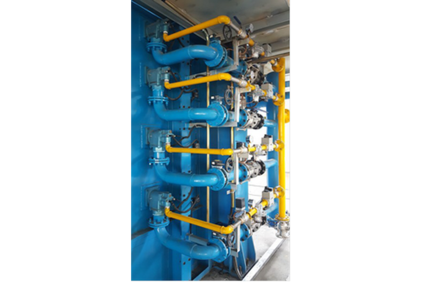

Ka mor'a ho hlaphoheloa ha mocheso oa litšila ho tloha ho preheating ea khase ea flue ea mohala oa galvanizing, e ka sebelisoa bakeng sa tlhokahalo ea metsi a chesang le ho futhumala ha litharollo tse fapa-fapaneng mekhoeng ea pele ea phekolo le ea ka mor'a phekolo ea galvanizing e chesang.Mocheso o hlophisitsoeng oa mocheso oa litšila o na le bokhoni bo phahameng ba phapanyetsano ea mocheso, taolo ea ts'ebetso ea skrineng, 'me e ka hokela komporong kapa mohala oa thekeng bakeng sa taolo e bonolo, e boloka likhoebo tse mashome a likete ho isa ho makholo a likete selemo se seng le se seng.

Ho hlaphoheloa ha mocheso oa litšila ho itšetlehile ka mochine oa mocheso, empa moralo oa tsamaiso o bohlokoa haholo.Sehlopha sohle sa morero oa ho khutlisa mocheso oa litšila se ka phethoa feela haeba mofuta, mocheso le mocheso oa mocheso oa litšila oa khoebo li lokiselitsoe hantle esale pele, 'me maemo a tlhahiso, phallo ea ts'ebetso, tlhokahalo ea matla ka hare le kantle, joalo-joalo li batlisisoa.

Ngola molaetsa wa hao mona mme o re romele wona