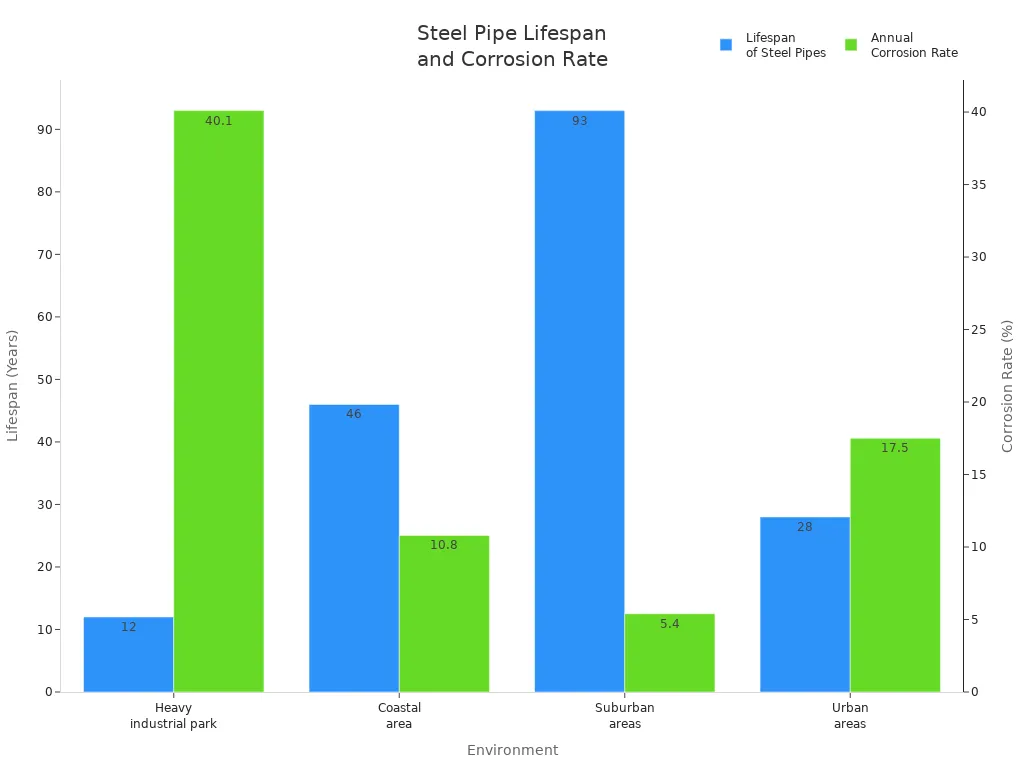

U sireletsa liphaephe tsa tšepe mafomeng ka ho sebelisa galvanizing e chesang.Lisebelisoa tsa ho khellisa ka galvanizing tsa tšepe tse chesang tse nang le phaephee koahela phaephe e 'ngoe le e 'ngoe ka zinki, e leng se etsang hore e be thebe khahlanong le mafome.Liphaephe Mela ea ho lahlathusa ho netefatsa hore qetello e tiile, e lekanang. Sheba chate e ka tlase. E bontša kamoo liphaephe tsa galvanized li tšoarellang nako e telele kateng libakeng tse fapaneng.

Lintlha tsa Bohlokoa

- Ho kenya ka galvanizing e chesange sireletsa liphaephe tsa tšepe mafomeng ka ho sebelisa lesela le teteaneng la zinki, le sebetsang e le thibelo khahlanong le mafome.

- Tokiso e nepahetseng ea bokaholimoHo bohlokwa haholo. Ho hlwekisa le ho ntsha diphaephe ho netefatsa hore zinki e kgomarela hantle, ho thibela diphoso tse ka hara lesela.

- Liphaephe tse entsoeng ka galvanized li fana ka ho tšoarella nako e telele, hangata li nka lilemo tse 40 ho isa ho tse 50, e leng se etsang hore e be khetho e theko e tlaase bakeng sa liindasteri tse fapaneng.

Mehato le Mehato ea Ts'ebetso ea Lisebelisoa tsa ho Khakanya ka Khabone tsa Pipe ea Tšepe

Phaephe ea tšepelisebelisoa tsa ho khellisa ka galvanizing tse chesange u thusa ho sireletsa liphaephe tsa tšepe mafomeng le tšenyong. U sebelisa lisebelisoa tsena liindastering tse ngata, tse kang tsa kaho, mechine, lifeme tsa lik'hemik'hale le literene. Lisebelisoa li sebetsana le liphaephe tse bophara ba lisenthimithara tse 1/2 ho isa ho tse 10 le bolelele ba limithara tse 4 ho isa ho tse 8. E ka koahela liphaephe ka zinki e boima ba ligrama tse 50 le 400 ka mithara e sekwere. Lisebelisoa li ka sebetsana le liphaephe tsa tšepe tse fihlang ho lithane tse 80,000 selemo se seng le se seng.

| Ntho | Tlhaloso |

|---|---|

| thepa | terata ea tšepe |

| sebaka sa bophara | 1/2 ~10 inch |

| bolelele ba phaephe | 4~8 m |

| mofuta oa ho roala | zinki |

| boima ba 'mele ba ho roala | 50~400g/m2 |

| bokhoni | 40000~80000T/selemo |

Ho Lokisetsa le ho Hloekisa Bokaholimo

O qala ka ho hlwekisa diphaephe tsa tshepe. Mohato ona o tlosa ditshila, oli le ditshila tse ding. Haeba o tlola ho hlwekisa, lesela la zinki le ke ke la kgomarela hantle. O hloka ho tlosa slag ya weld, di-burrs, sekala sa mill, di-varnish, di-epoxies, lehlabathe, dipente tse thehilweng oling, matshwao a crayon, le boka bo teteaneng kapa mafura. O sebedisa dibate tsa ho tlosa mafura ka sodium hydroxide ho tlosa oli le mafura. Kamora ho tlosa mafura, o hlatswa diphaephe ka metsi. Ebe o sebedisa hydrochloric kapa sulfuric acid ho tlosa mafome le sekala sa mill. Mohato ona o bitswa pickling.

Keletso: Kamehla hlatsoa liphaephe ka mor'a ho hloekisa asiti ho tlosa mesaletsa eohle ea asiti. Omisa liphaephe ka botlalo pele u fetela mohatong o latelang.

Ho Hlakola Liphaephe tsa Tšepe

Ka mor'a moo, o qoelisa liphaephe ka tharollo ea flux. Fluxing e tlosa li-oxide tse setseng 'me e thibela oxidation e ncha pele u koahela liphaephe ka zinc. U sebelisa tharollo ea zinc ammonium chloride bakeng sa mohato ona. Mocheso o motle ka ho fetisisa oa ho flux ke pakeng tsa 60 le 80 °C. Mocheso ona o thusa flux ho hloekisa bokaholimo ba tšepe hantle. Lisebelisoa tse ka sehloohong tsa fluxing ke zinc chloride le ammonium chloride. Lik'hemik'hale tsena li tlosa oxide ea tšepe le ho ntlafatsa phallo ea zinc. Fluxing e boetse e u thusa ho sebelisa zinc e nyane le ho fokotsa litšila.

- Kloride ea zinki: 60–80%

- Ammonium chloride: 7–20%

- Lisebelisoa tsa ho fetola mokelikeli: 2–20%

- Metswako e meng: nickel, cobalt, manganese, loto, tin, bismuth, antimony

Ho qoelisoa ka Bateng ea Zinki

Ebe o qoelisa liphaephe ka bateng ea zinki e qhibilihisitsoeng. Lisebelisoa tsa galvanizing tsa phala ea tšepe li boloka bate ea zinki mochesong o nepahetseng, hangata li pakeng tsa 825 le 870 °F (440–460 °C). U boloka liphaephe ka bateng metsotso e 5 ho isa ho e 15. Lekhetlong lena u lumella zinki ho hokahana le tšepe 'me u etse seaparo se matla, se lekanang. Bate ea zinki e koahela karolo e 'ngoe le e 'ngoe ea phaephe, esita le ka hare le ho potoloha li-weld.

Ela Hloko: Haeba o sa laole mocheso kapa nako, o ka nna wa fumana diphoso tse kang di-pimples tse manyala, matheba, kapa ho petsoha.

Ho Pholisa le ho Hloekisa ha ho Qetela

Kamora ho ntsha diphaephe ka bateng ya zinki, o di phodisa ka tankeng ya ho tima. Ho phodisa ho emisa dikarabelo pakeng tsa zinki le moya. Ebe o hlatswa diphaephe ka metsi a hlwekileng ho tlosa dikhemikhale tse setseng. Haeba o sebedisitse ho hlwekisa asiti, hlatswa diphaephe ka lekgetlo la bobedi. Omisa diphaephe ka moya o futhumetseng ho netefatsa hore ha ho na mongobo o setseng. Mohato ona o boloka bokahodimo bo hlwekile mme o thibela mafome a masweu.

- Hlatsoa ka metsi a hloekileng

- Omisa ka moea o futhumetseng

- Boloka liphaephe sebakeng se omileng

Tlhahlobo le Teko ea Boleng

O tlameha ho hlahloba liphaephe ho netefatsa hore kobo e tiile ebile e lekana. O sebelisa liteko tse bonahalang, litekanyo tsa botenya le liteko tsa ho lekana. O boetse o hlahloba hore na phaephe e thata hakae, e senyehile hakae, ebile e senyehile hakae. O lekanya boholo ba phaephe mme o batla ho dutla ha metsi. O latela maemo a kang ASTM A500 le EN 10219. Maemo ana a o thusa ho netefatsa hore liphaephe di tla tšoarella mme di hanele mafome.

Mokhoa oa Tlhahlobo Tlhaloso Tlhahlobo ea pono Hlahloba boreledi, diphoso le mafome Botenya ba lera Sebelisa limithara ho lekanya botenya ba ho koahela Ho tšoana Batla ho peoloa kapa ho koaheloa ho sa lekanang Ho ba le makukuno Teko ea bokaholimo bo thata Tlhahlobo ea ts'enyeho Fumana mengoapo kapa tšenyo Boleng ba ho tjheseletsa Hlahloba mapetso kapa litšila Sebopeho sa lik'hemik'hale Leka tekanyo e nepahetseng ea zinki le tšepe Boitšoaro ba mechine Lekanya matla le ho tenyetseha Tlhahlobo ea litekanyo Netefatsa bophara, botenya le bolelele Letšoao le ho tšoaea Hlahloba mabitso a nepahetseng Teko ea ho lutla Etsa bonnete ba hore liphaephe ha li na mapetso kapa masoba Khopotso ea Polokeho: Kamehla latela melao ea polokeho ha u sebelisa lisebelisoa tsa tšepe tsa galvanizing tse chesang. Hlahloba liphaephe bakeng sa tšenyo 'me u netefatse hore boleng ba metsi bo botle ho thibela ho bola.

Melemo ea Lisebelisoa tsa ho Khantša ka Khabone tsa Pipe ea Tšepe

Tšireletso e Phahameng ea Mafome le Mafome

U fumana tšireletso e matla khahlanong le mafome ha u sebelisalisebelisoa tsa ho khellisa phala ea tšepe tse chesang. Sekoahelo sa zinki se etsa mokoallo o teteaneng o thibelang metsi, moea le lik'hemik'hale hole le tšepe. Mokoallo ona o sebetsa hantle ho feta pente kapa likoahelo tse tšesaane. Zinki e boetse e sireletsa tšepe haeba koahelo e ka ngoapa. Zinki e tla bola pele, e boloke tšepe e ka tlase.

- Lera le teteaneng la zinki le mamella boemo ba leholimo bo bobe le lik'hemik'hale.

- U bona mokhoa ona o sebelisoa bakeng sa marokho, literene le liphaephe tsa kantle hobane o nka nako e telele.

- Sekoahelo sa zinki se sebelisa tšireletso ea tšireletso le ea sehlabelo, kahoo liphaephe tsa hau li lula li sireletsehile leha bokaholimo bo ka senyeha.

Lithuto tsa mahlale li bontša hore zinki e etsa metsoako e khethehileng, joalo ka ZnO le Zn5Cl2(OH)8, e liehisang mafome le ho boloka liphaephe li le matla libakeng tse thata.

Mokhoa Tlhaloso Tšireletso ea Litšitiso Lera la zinki le thibela metsi le moea ho fihlela tšepe. Tšireletso ea Boitelo Zinki e bola pele ho tšepe, e e sireletsa leha e ka ngoatheloa. Boemo ba Leholimo ba Tlhaho Ha nako e ntse e ea, zinki e etsa likarolo tse eketsehileng tse eketsang tšireletso e eketsehileng. Ho Tšoarella ho Ntlafatsang le ho Phela Nako e Telele

O ka lebella hore liphaephe tsa galvanized li tšoarelle lilemo tse mashome. Ha lesela la zinki le le teteaneng, liphaephe tsa hau li tla tšoarella nako e telele. Mohlala:

Mofuta oa ho roala Nako e Lebeletsoeng ea Bophelo Libakeng tse Mahareng G30 Lilemo tse 5–10 G90 Lilemo tse 20 kapa ho feta Bongata ba liphaephe tsa galvanizing li nka lilemo tse ka bang 40 ho isa ho tse 50. Libakeng tse omileng, li ka nka nako e telele le ho feta. Haeba u sebelisa lisebelisoa tsa galvanizing tsa phala ea tšepe tse chesang, u thusa liphaephe tsa hau ho hanela mafome le tšenyo ka lilemo tse ngata.

- Liphaephe tse libakeng tse mongobo o tlase li ka nka lilemo tse fihlang ho tse 70.

- Libakeng tse metsi kapa tse letsoai, nako ea bophelo e ka ba khutšoanyane, empa e ntse e le telele haholo ho feta tšepe e sa koaheloang.

Ho Sebetsa ka Botlalo le Tlhokomelo e Tlase

U boloka chelete ha nako e ntse e ea ka liphaephe tsa galvanized. Litšenyehelo tsa pele li phahame hanyane ho feta pente, empa u sebelisa chelete e nyane ho lokisa le ho hlokomela. Papiso e khutšoanyane ke ena:

Mokhoa oa Tšireletso Litšenyehelo tsa pele Tebello ea Bophelo (lilemo) Litšenyehelo tsa Tlhokomelo NPV Ho Chesa ka Galvanizing 100 25 0 100 Sistimi ea Pente 90 8 169 169 Liphaephe tse entsoeng ka galvanized ha li hloke ho hloekisoa haholo le ho lokisoa hanyane. Ho koaheloa ha tsona ka matla ho bolela hore ha ua lokela ho tšoenyeha ka mafome kapa ho lutla khafetsa. Sena se etsa hore e be khetho e bohlale bakeng sa merero e meholo le libaka tseo u batlang hore liphaephe li tšoarelle nako e telele ho tsona.

Lisebelisoa tsa galvanizing tse nang le galvanizing tse chesang li u thusa ho sireletsa liphaephe tsa tšepe ka lilemo tse ngata. U fumana ts'ebetso e tšepahalang libakeng tse fapaneng.

- Ho tšoarella ha nako e telele ho itšetlehile ka maemo a tikoloho.

- Litsebi li remohato o mong le o mong oa ts'ebetso o amaboleng le matla a ho roala.

Mohato Tšusumetso ho Katleho Ho hloekisa E ntlafatsa ho khomarela le ho thibela liphoso Ho seha E ama boreledi le boleng Ho phutholoha E netefatsa phallo e ts'oanang ea zinki Ho qoelisoa E laola botenya le boleng ba kahare Tlhahlobo E netefatsa hore ho koahela ho fihlela maemo a tloaelehileng

Nako ea poso: Loetse-11-2025